From field to cellar: a chronology of lavender distillation

Once the harvested flower is brought to the distillery, it is important to make sure it enters the still in premium condition. The flower is laid out on tarps, cleared of any extraneous plant matter and tossed with a pitch fork, to assist air circulation around the flower. This helps to maintain fresh condition, or, if progress to the still is delayed, allows the flower to gently air dry. Lavender can be distilled fresh or dry and while we work the flower close to still time, sometimes it is more desirable to get the flower off at the right time and to dry it. When this is the case, the flower needs to be turned twice daily if drying is to be successful.

Along with care of cut flower, packing the still is critically important to successful distillation. If the flower is not compacted evenly in the distillation chamber, the steam will naturally find the easiest path out and steam will not envelope all, of the flower. Because we are small scale distillers we compact flower into the still by way of stomping.

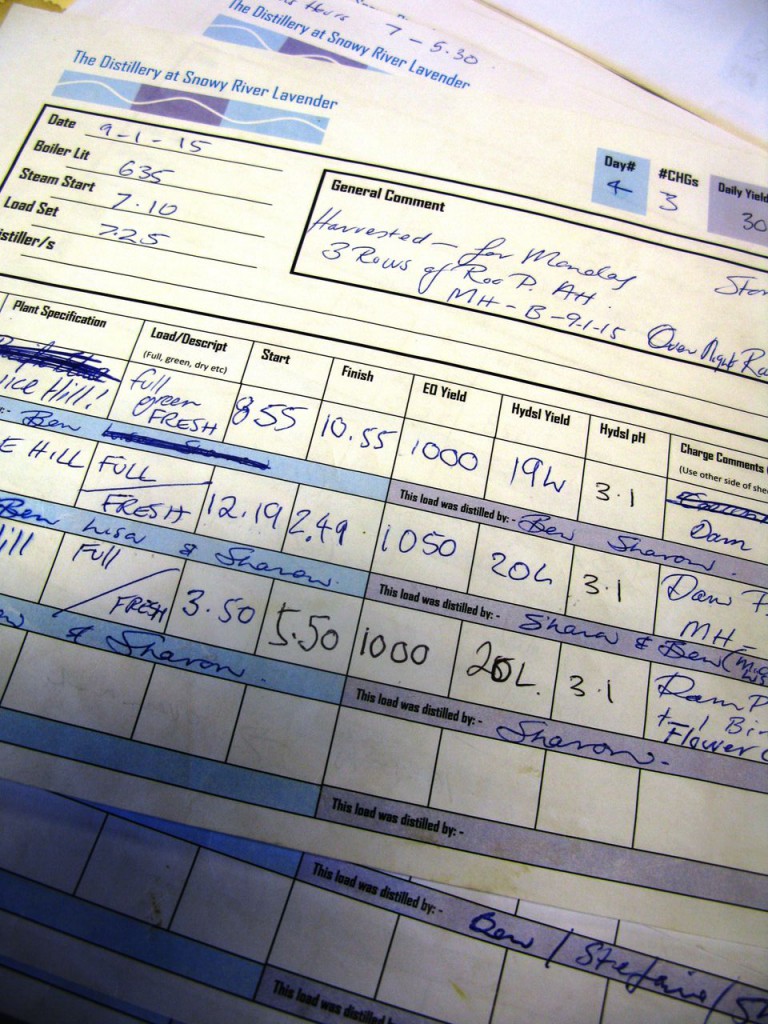

Once packed, the distillation chamber is swung into place on to the still base. The still set is completed when the condenser lid is clamped into place. Once set, steam is pumped into the distillation chamber and distilling is underway. Distilling demands care, knowledge, vigilance and record making. Our distillations run 2 hours for the lavenders, and two and half for the lavandins, after which, the still is unloaded and the process is set to go again.

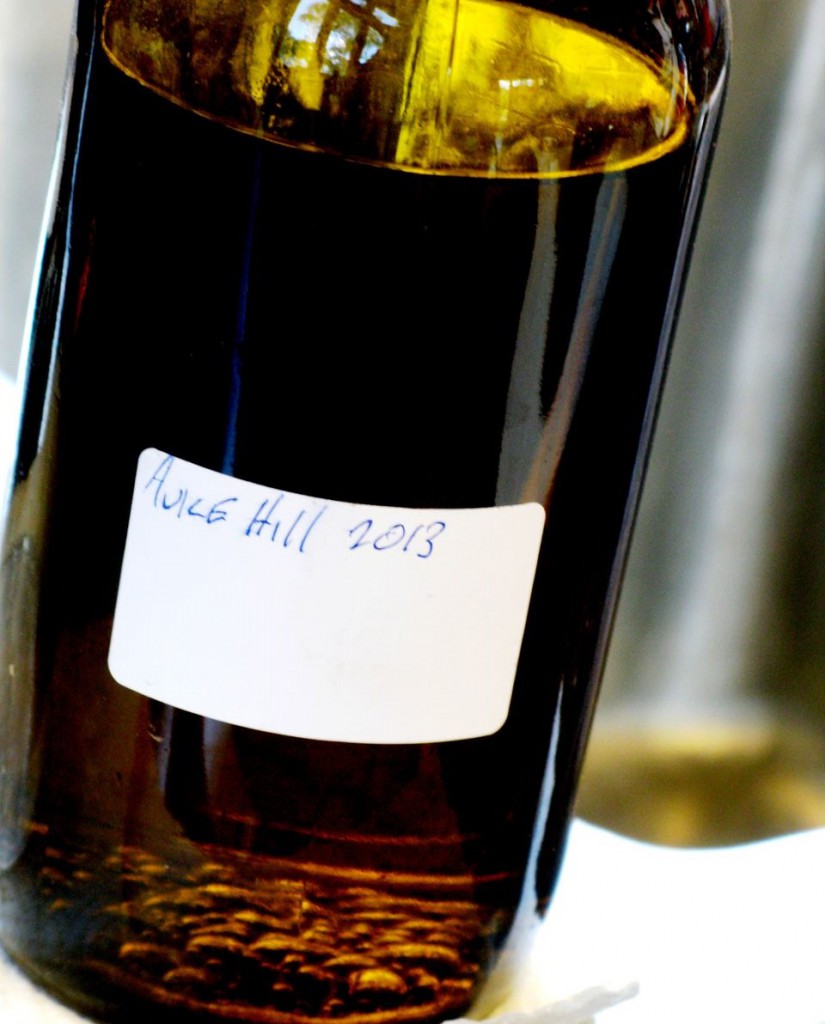

Essential oil is tapped into amber glass bottles and hydrosol into heavy duty plastic cubes. Both are cellared cool, dark and airtight. Essential oils are allowed to sit for 2-3 months and then go through a drying out process where any residual hydrosol is removed. When rebottled the head space above the essential oil is filled with nitrogen vapour to prevent any oxidisation. Both essential oils and hydrosols are cellared for twelve month before being released for sale.

Pre-Distillation Processes

Distilling

Post Distillation